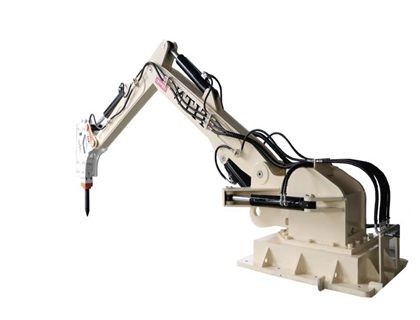

Stationary hydraulic crushing station

Product details

TTP series fixed crushing station (hereinafter referred to as crushing station) is mainly used for the secondary crushing of large pieces of material at the inlet or grid of various mines and quarry crushers. The product has large crushing capacity, stable operation, low noise, reliable performance, convenient operation, and can effectively reduce the labor intensity of workers, improve the on-site working environment, and improve work efficiency. Years of experience tells us that an accurate understanding of user needs is good. The combination of partnership and high-quality equipment will bring better results. Combined with the various conditions and requirements of the mine, the fixed crusher selected by our company fully meets the use requirements of most mines. The cab is fully sealed with air-conditioning, creating a better working environment for workers!

Product technical performance

1. The breaker selected by our company is the GBT series of Korean engineers. With super striking force, the output of oil is maximized, so as to improve the work efficiency, improve the quality of work, durable, easy maintenance, and quick after-sales service. The GBT series breaker can crush 30 tons of ore per hour, with a fragmentation of about 1.5m³, and the maximum crushable rock hardness coefficient is F17. All indicators meet and exceed the working conditions of most mines.

2. After strength check and aging treatment, the structural parts are made of high-strength structural steel by stamping and gas shielded welding, which can withstand strong loads. The working arm's farthest crushable distance is 5.3m, the nearest crushable distance is 2.2m, the span is 3.2m, the working coverage area is 4m×4m, the rotation angle is 120°, and the maximum working height is 3.5m, which can cover most of the input material. Orifice or grid sieve area.

3. The main components of the hydraulic system such as constant pressure variable pump, hydraulic proportional multi-way valve, pilot control valve, balance valve, buffer valve, etc. are imported or domestic high-quality brand manufacturers, the operation method is simple, flexible, efficient, reliable, and high safety factor , Energy saving and consumption reduction, smooth operation.

4. The electric control device is driven by an AC 380V50HZ motor. The system controls the pressure, oil level, oil temperature, working time, etc., and has alarm indications. The PLC centralized control device and line connection adopts a higher degree of protection (IP54), stainless steel The shell is clean, energy-saving, low operating cost, strong adaptability, and can be used in various harsh environments such as high temperature, high humidity, and high dust concentration.

5. The cooling system uses an air-cooled cooler to control the oil temperature of the system, which provides protection for the long-term operation of the equipment, provides protection for the use of hydraulic components and wearing parts, and extends the service life of the whole machine and parts , Reduce the cycle of after-sales maintenance.

6. The cab adopts a sealed air-conditioned cab with a reasonable ergonomic layout, which provides operators with a more comfortable and relaxed working environment.

7. After spraying with shot blasting and derusting, apply military aircraft carrier derusting primer to make the equipment have stronger anti-rust, anti-corrosion ability and longer service life under open-air working conditions.